Packaging 101: The Basics of Corrugated Packaging

TYPES OF CORRUGATED BOXES

Half-Slotted Boxes (HSC): Consist of one piece with a glued, stitched, or taped manufacturer's joint and top and bottom flaps. They are shipped flat, ready to use, and require closing using the flaps provided.

Slotted Boxes (RSC): Consist of one piece with a glued, stitched, or taped manufacturer's joint and top and bottom flaps. They are shipped flat, ready to use, and require closing using the flaps provided.

Folder Boxes & Trays/Mailers: Usually consist of only one piece of board. The bottom of the box is hinged to form the side walls and the cover. Locking tabs, handles, display panels, etc., can be incorporated in some designs.

Telescope Box: Consist of more than one piece and are characterized by a lid and/or bottom telescoping over the body of the box.

Partitions: Corrugated partitions are primarily used to create compartments in your packaging to separate and store multiple products in one box. Box partitions can be corrugated for extra protection of fragile products during transit, or made with lightweight paperboard for smaller items.

Pads & Sheets: Used as a layering pad on pallets to disperse weight. Pads help keep tops of products dust free during storage, while also preventing strapping and forklift damage during shipment.

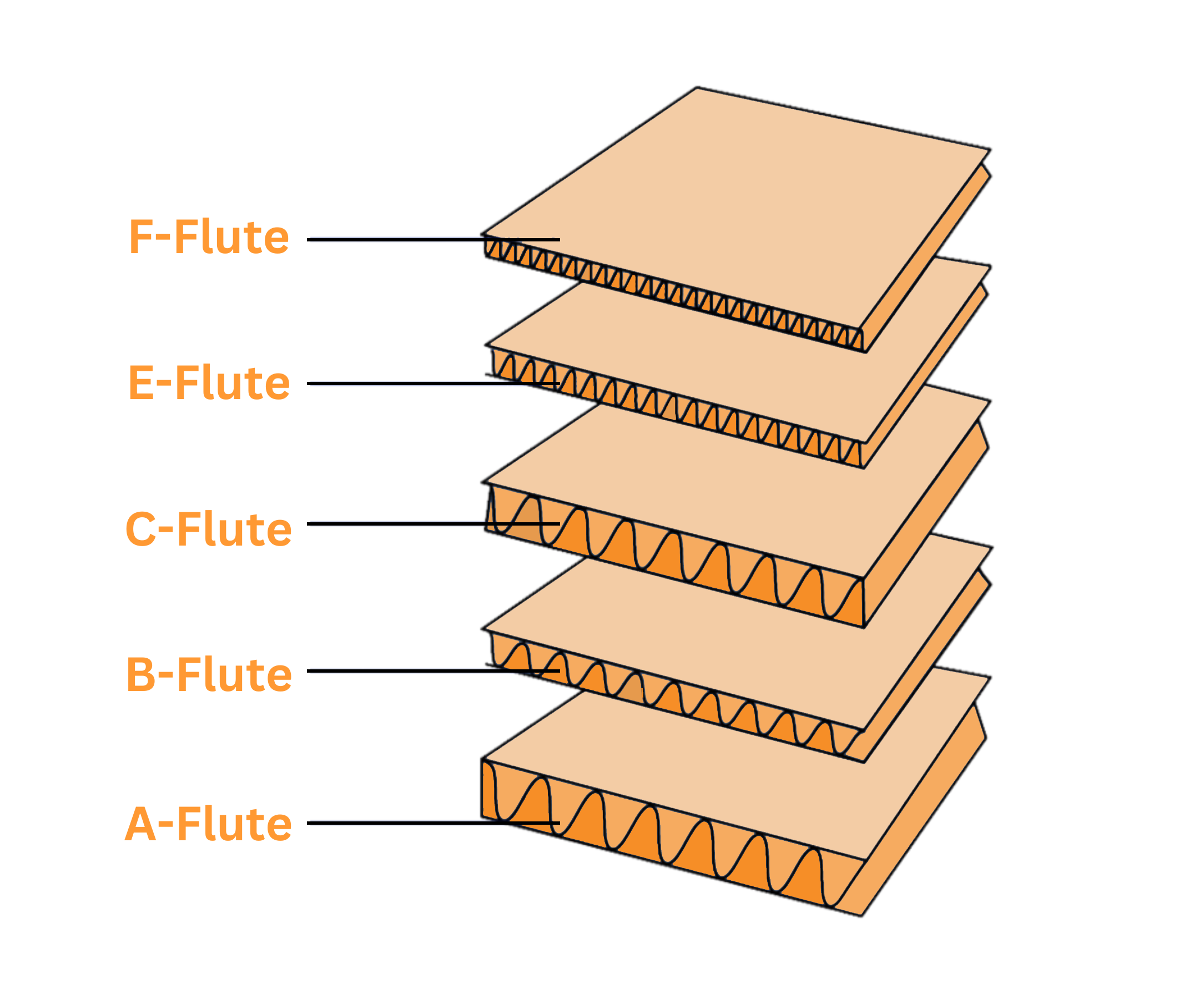

FLUTES

This refers to the wave shapes, or ridges, that are pressed into a sheet of material. This material is then sandwiched between flat sheets of material to form corrugated fiberboard. Flutes serve as protective cushioning and help strengthen a carton. Different widths and configurations offer distinctive performance advantages.

A-Flute: Flute thickness of 4.7 mm

B-Flute: Flute thickness of 2.5 mm

C-Flute: Flute thickness of 3.6 mm

The above three flutes are the most common corrugations used in single-wall, general-purpose cartons. A-Flute has excellent stacking strength, B-Flute has good puncture resistance, and C-Flute has the optimum combination of both.

The next three flutes serve other purposes. E-Flute and F-Flute are the thinnest corrugations, while BC Flute and AC Flute provide extra strength.

E-Flute: Flute thickness of 1.5 mm and is generally used for light applications such as pizza boxes, mailers, shoe boxes, etc.

F-Flute: Flute thickness of 0.8 mm and is usually used for the light-weight products packaging when durability and stiffness is a requirement.

BC Flute: This flute is a double-wall combination made from one B-flute, single-wall sheet and one C-flute, single-wall sheet. The result is a strong corrugation used when extra thickness or stacking strength is needed.

AC Flute: This flute is a double-wall combination made from one A-flute, single-wall sheet and one C-flute, single-wall sheet. The result is a very strong corrugation used when extra strength is needed.

CORRUGATED TESTS

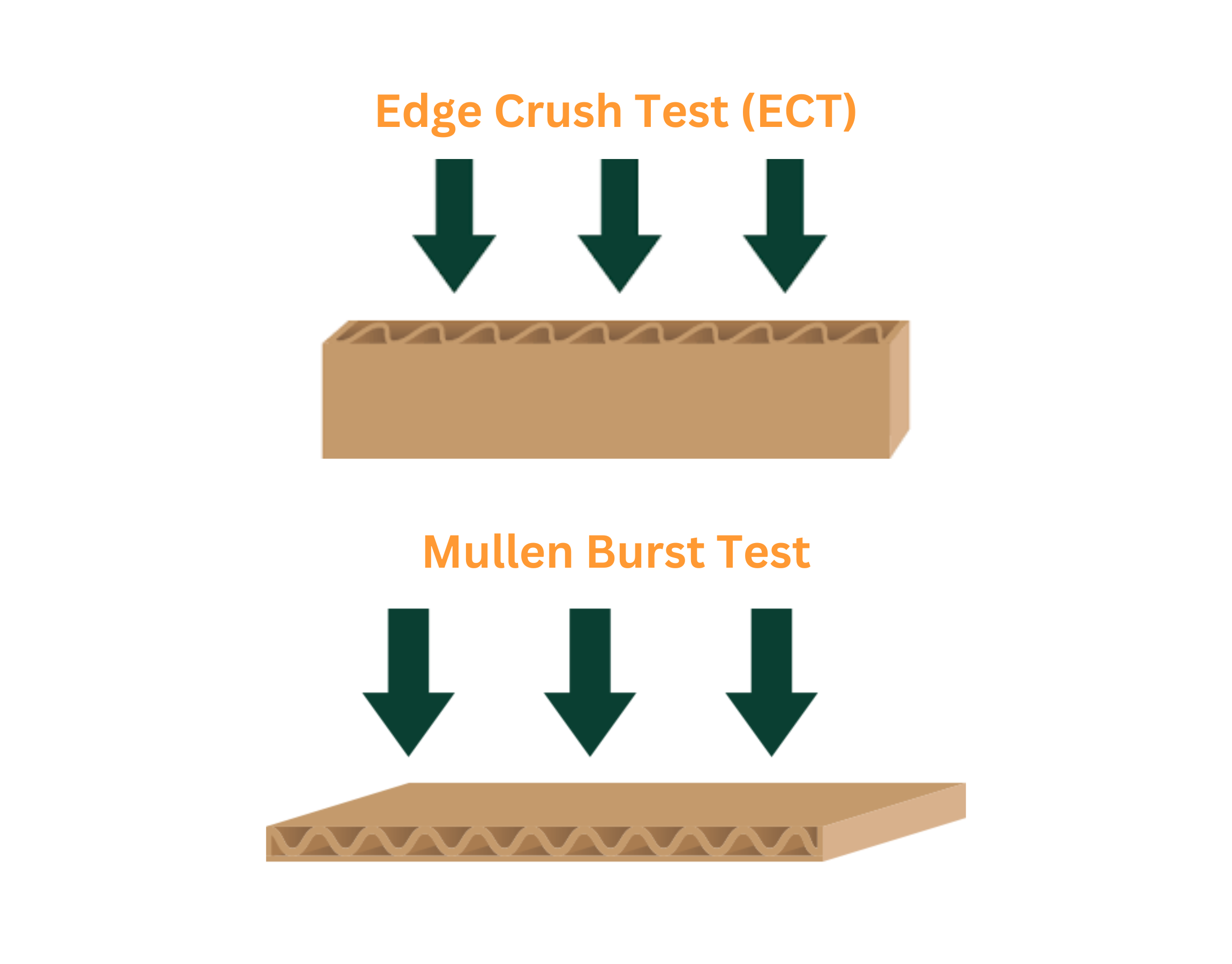

Mullen Burst Test: Measures bursting strength of the corrugated board. The Mullen test presses a rubber diaphragm bubble against the board in a defined area to measure the pounds of pressure per square inch (psi) it takes to burst the board. Many customers like Mullen tested boxes for the protection of heavier contents because they are concerned about the linerboard bursting outward.

ECT (Edge Crush Test): Measures the box board’s top-to-bottom compression strength (also known as stacking strength). This test looks at two areas of strength: box compression strength (BCT) and stacking strength. If a customer is concerned about the maximum weight a box can withstand, then ECT is your test. Today, this is the most common type of test used.

Basis Weight Testing: A measurement of mass per unit of area that is expressed in pounds per thousand square feet. Basis weight is used to describe linerboard, corrugating medium, and boxes.

ISTA Testing: Performance testing specified by the International Safe Transit Association. Generally includes testing of shock and vibration effects on packaging.

HAZMAT/UN Testing: Shipment of dangerous goods or hazardous materials are highly regulated. Based on the UN Recommendations on the Transport of Dangerous Goods model regulations, each country has coordinated design and performance requirements for shipment.